|

|

#21

|

||||

|

||||

|

There is no stage 3 motor for the Gen 1's... And yes, the stage 1 arms are the same [I think]. All in the gearings. Same with the stage 2 arms. But they have a lower wind count [Correction?] You can pop those into a Evo can with ease, but you would have to remove the pinnion from the S1/S2 arm first. As for speed, not quite sure. I'll let Red, or XMDrifter take that one.

Back on topic, how great would one of those motors be on the track? Thinking about comparing a couple motors from different places/modders. Quick! Someone get Red's homework done! So he has time working on the different winding patterns and such!! Hurry!! |

|

#22

|

||||

|

||||

|

Quote:

they just had to name it differently on the site since you can't have more than 1 thing with the same name. if it's not by radioshack, then i have no clue as to how many winds it has. s1 has 60+ winds. s2 has 54 winds you're right dspamme anyways, it'd be the same if you just stuck a s2 arm from a gen 1 can into a evo can. same speed, same everything. though there is a slight difference in the shape that gen1 and evo arms are built, it's not significant. red, don't you find winding gen1 arms easier than evo arms? cuz you can remove the plastic sheilding thing and there's peg holes for the comm in the actual metal?

__________________

|

|

#23

|

||||

|

||||

|

Motor testing results Week of November 17th

Well, I did some motor building this week (the one thing I did besides deer hunting, lol) and not to mention lots of testing and experimenting. In a discussion that Flashsp-2 got into a while back, we brought up the availability (or the lack there of) of specialty blank armatures (ie, slotted, spiral slotted, long) and the such. Auldey is the company, however, they don't seem to produce these anymore. They were origninally intended for Tamiya Mini4wds, and some smart bloak figured to use them in our motors. Problem is, there is limited supplies. I purchased 5 blank spiral armatures, and 2 FAT commutators (1 silver, 1 copper) from a dealer in the UK (xmodded.uk) and recieved them a while ago and have been doing some testing with them. I found a few interesting facts that average motor builders may not realize right away: So between 7 armatures (techincally 6, ones on its way to SPR), 5 spiral and 2 regular I found that the spiral armatures had much more room on the poles than regular RS armatures. The pole was also thinner. While this translates to more winds on the pole, I was pleased to see that it kept the stack patterns alot lower, and closer to the iron laminations. This, at least so it seems to me, increases the motors efficiancy. It seems that the closer the top layer of the stack pattern is to the pole, the stronger the armature. Instead of having a 42t pyramid with 7 layers, I had a pyramid with 5 layers, and 1 wind on the head of the pole. Much easier to wind, IMO, plus more effcient. The 15 degree spiral twist on the armature also had a devastating effect. Since the stack pattern was delightfully low profile, I expected the low end torque to be lacking, because the winds would be shorter than a taller stack, however, the torque was off the chain even with Iso mags! With basic armatures, you get dead spots between the poles/coils. In effect, the spiral armature twists the coils over some of these dead spots, increasing magnetivity which in the long run transfers to torque. So not only did a 41t with a FAT comm outperform (torque wise) a 42t, it beat out a straight wound 39t with a standard comm/rs armature. Hemi winding too, is one thing I'm going to be doing alot more of. Although it seems backwards to me, changing the direction of the winding has no effect on the direction the motor will spin, because electricity always flows through it the way it usually does (the wire technically does a full 360). I hemi wound all of the spiral armatures so far, and they seem much smoother than typical cross wound motors. Of course, alot of this isn't noticeable when dropped in a typical xmod someone using fine precise drivetrains (ie, blt45's 64 pitch differntial) will feel the response, especially on a flat smooth surface such as a carpet, or rcp track. Another item I got to experiment with was the silver FAT commutator. BOOM!! Thats all I could think of when I tested it, lol. Its as big around as any FAT comm, its just instead of copper plates, it uses silver, an element probably twice as conductive. The results, IMO were devastating. The armature I wound 35t hemi wound, standard short RS armature was explosive in its response. Every bit of juice flowing into that motor found the silver. It seems that some motors don't use the given power very well. Arcing and poor commutator conductivity can often times be the culprit. The silver comm with fully broken in carbon brushes was deadly. The low end was raised slightly, and top end stayed about the same, but the response was great! I'll be getting more of these if I can... The hemi wound motors have equal discharge times on a 1.5v AA battery, as compared to a standard cross wound armature, however, the spiral motors last a minute or so longer than standard. Taking into consideration the differences in pole lengths, though, its not surprising. I'm trying to develop a motor right now that peaks out run time on NiMh batteries, as that would be a very big hit with racers. However, this can be tricky, and I have a feeling a gRed (check my SP thread) armature would be better than a spiral or other type. Overall, my motors are headed more in the direction of speedy response, and smooth operation as of the November. However, that doesn't mean that they will be wimpy. Combine fast response with torque and high top end, and you've got an almost perfect motor. If I can get a source for specialty motor parts, they will deffinately be incorporated into my motor lineups. Feel free to comment or respond. Later, RedSXmodder |

|

#24

|

||||

|

||||

|

nice write up red. One ?: Any "hemi-wound" pics?. As for the armatures i have(spiral and slotted, left i believe, have copper fat comms). The "special motor" still hasn't been tested, xmf hasn't rated my tuts for points.. I might be able to send you some of those arms to test, once i get my track setup ready.

__________________

Track car v2.0 fieldfairy2's mini late model Operation black widow H-Crawler

|

|

#25

|

||||

|

||||

|

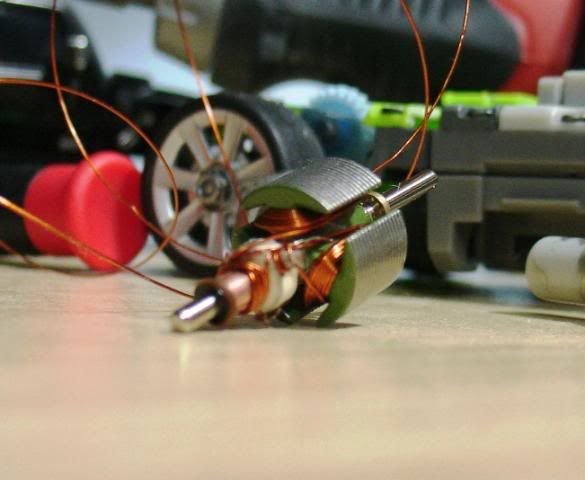

Ok, so after reading various articles written by you, i decided to finally try it. I made a 28T Arm with 30g wire. Its a stock stage one arm. This is NOT a functioning motor. I just wound it over and over again till I think I got it right. The wires are not soldered to the contacts. I am just practicing winding. Keep in mind that this is my VERY FIRST attempt. The first pole was done in 5 min. and the second took me over an hour. Lol.

Without further due: When I was done 2 poles:     And the (non-working) finished product:     Comparison between a Chilli arm and my arm(just for fun):   So, what do you guys think? And Red, PLEASE give me feedback and criticism. ALL C&C Welcome EDIT: I forgot to mention that I have NEVER, NEVER made a normal wind motor. My first one is this one. Later T.I.M

__________________

"Where There's Will, There's A Way" "Many Of Lifes Failures Are Those People Who Did Not Realize How Close They Were To Success When They Gave Up"  |

|

#26

|

||||

|

||||

|

looks nice, except that the comm just looks messy, but the stacks look neat.

yeah, hemi wind is when instead of winding like you see on most motors, where the wires "cross" in between motor tabs, you attatch the wire to the tab and go straight down on the pole instead of across to the opposite side of the pole. ____Tab____ ____|---____ ____|---____ ____V--____ in that direction hey red, post up some snaps of your armatures

__________________

|

|

#27

|

||||

|

||||

|

Hey guys! I'm gonna try pattern winding my first motor for stock FETs and a stock can (that's all I can afford right now XD). I want to know where you can buy spiral armatures (for future reference of course). I didn't find any on xmodded.co.uk. Also can you tell me how the wire should look when attached to the commutator? Would a pattern wound 45t motor fry my FETs? Or should I buy an FET upgrade just in case?

Last edited by Pwnzor1130; 04-04-2009 at 10:22 PM.. |

|

#28

|

||||

|

||||

|

the motor armatures you can't buy anymore. the companies stopped manufacturing them and selling them. you'll have to get old stock motors and open those up and take the armature out of those. motor winding needs you to be able to solder presicely and to wind consistently. also you have to have a fine touch to ba able to scrape the enamel off of the winding wire without cutting the enameled wire in two.

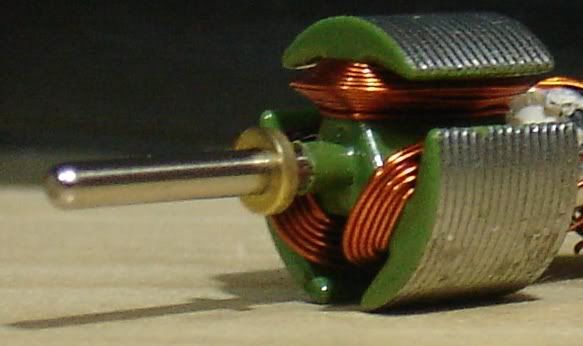

a pic of how it should look: http://i155.photobucket.com/albums/s...r/CIMG0212.jpg that's one of mine. it's a double wound one, so there's actually 2 strands of wire per pole this was wound on a xmod stage 1 armature(you'll have to take all the old wiring off of it)

__________________

|

|

#30

|

||||

|

||||

|

you don't need to use the stock can. all armatures are (except maybe a few) standardized in size.

you can take the stock arm and rewind it. don't need to buy a whole new motor. after you rewind it, it'll fit into virtually any motor can. (you might have to take some of the little thin plastic washers off the ends)

__________________

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|