|

|

|

|

#1

|

||||

|

||||

|

Motor Guru's speak up!

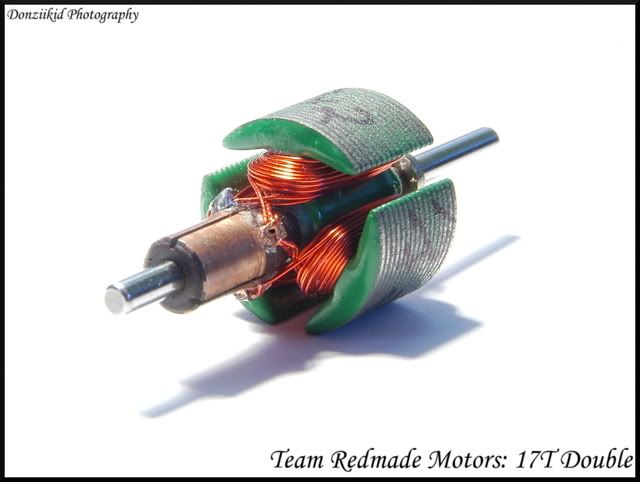

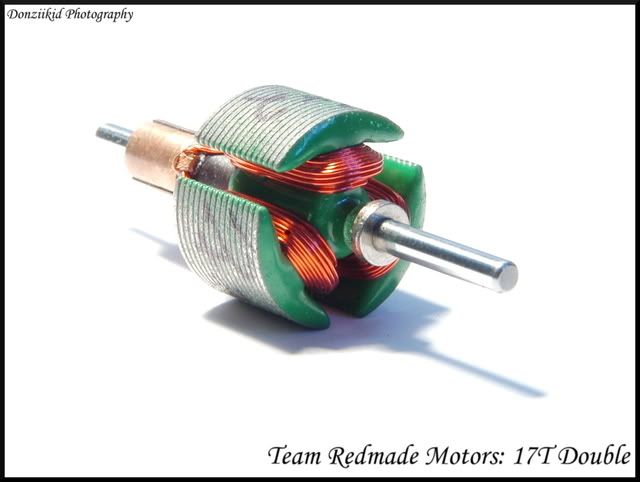

Okay, so I know I already made a thread talking about motors and how they work, but I'm not making this thread to get a sticky. If you would like to add something, comment on something, or ask a question about anything mentioned PLEASE feel free to do it! I don't bite (often) and will be more than happy to answer any question that you may have involving the motor. Now, some of the stuff I'm gonna talk about, and the other more advanced members will talk about may be difficult to understand. If you are interested in what is being discussed, please feel free to ASK! I've leared a ton of stuff by asking questions, and I wouldn't be where I am today if I didn't ask. So, where do we begin? I'll start by saying this. Your motor is an essential piece of your car, and if not maintained properly, will not perform the way it should. Look at your motor not as a piece of electronics, but as a suspension system for a few seconds. You can adjust your suspension by switching springs, and adjusting tie-rods, but what about that guy thats adjusting his springs, his preload, tie-rods, tweak AND his droop? His suspension system will be way more refined than the carelessly built system I mentioned previously. That is how we should look at motors. If your going around thinking your the best because you bought some motor that is supposed to be super awesome, you pop it in, and let it rip, and call it at that you should think twice! Take for example the guy who purchases a blank armature, pattern winds it, breaks it in, water dips it, adjusts his motor brushes and properly maintains everything. His motor will be much better than the motor that so and so purchased from some large online buisness. When making a decent motor, it is essential that you take in everything that goes on inside. If something is mis-aligned, or you don't run the gearing right, your not getting the most out of your motor. I look into every lettle detail when I build a motor, and it shows in performance. What I wanna talk about now, is how you guys, and I myself build, and properly tune motors: The Ideal High Performance Motor: Of course, it will be different in different situations, but lets take for example RCP/Carpet Track Racing. If you jump up a couple scales, you'll notice that motor care and tuning in ESSENTIAL to winning races. Look at the motors by Team Checkpoint, Epic, and Reedy. Whats one thing they all have in common? Adjustable brush springs, adjustable timing, Large cooling vents, high performance brushes/brush hoods, and powerful magnets. These fine adjustments help racers win, and when your motor is tuned properly, you will do better, guaranteed. But how to we get these features on motors this small? Easy, Atomic released the M1 Motor Case Kit almost a year ago. This motor case has Adjustable brush springs, large cooling vents, a hobby grade brush system, ball bearings, and powerful magnets. What more could we ask for? That makes this case the ideal case for any serious RC racer! But thats just a motor case, now we need to get into what makes the motor work. The armature. Yeah, the armature that comes in alot of factory built motors works, and they do a good job. BUT, if you are serious about your game, you know that there is always room for improvement. Thats where you get armature options. Slotted, Long, Spiral and Spiral Slotted are armatures that are available for winding on. Each has its advantage at the track. FAT comms are also a great add on. They enable your motor to tolerate higher current, and they last longer, too. Pattern winding is the thing that makes a track motor a track motor, and seperates the men from the boys. With Pattern Winding, your motor runs, cooler, faster, longer and you have more adjustment features (which I will talk about later in the thread). A specifically designed Pattern Wound Armature is the ideal setup for any serious racer! Proper motor maintenence is not just maintenence, it helps your motor run better! It will increase performance if done right! One important thing to do is breaking in your motor. Stock Brushes are typically not adapted to the face of the commutator, so that all of the brush is not touching the comm. With break in, it shapes the brush with the arch of the commutator, so that all of the brush is touching. This increases conductivity, which traslates to better motor performance. Comm drops are also a very good thing to use. It keeps the commutator smooth, reduces friction, and extends life of your brushes and your commutator. If done right, maintaining your motor will get you better performance and win you races! -------------------------------------------- Winding Discussion: Pattern Winding helps right? Yes it does. Alot. When the motors winds are tighter, and placed in a distinct pattern the results are devastatingly awesome! It cuts resistance down significantly, helps your motor run cooler, helps your motor run longer, and even makes your motor faster! The only negative side to pattern winding is the time it takes, and the skill required. What many people don't realize about it though, is that it is a very fine tuning tool. Instead of going with the wind counts factory motors make you settle with, you can choose a wind count that suits your driving style! If your number is 31t, or your number is 42t, it doesn't matter. Thats not the best part though. Think of wind count adjustment as a coarse tuning tool! It gets more refined than that Red? Hell yeah. Stack pattern, placement, height, and width are all factors that effect the powerband of the motor your running. Take for example a 33t motor with a high stack pattern placed closer to the edge of the pole. The tall stack pattern may be narrow, but it is longer. The wire needs to be longer to make it around the top of the pyrimid. This increases the power. It's kinda like adding a 1/2 wind to the count. Now, look at the placement. Closer to the edge of the pole? Why? When the rotational mass is shifted to the outside it faintly lowers RPM, but increases the torque ever so slightly. This armature in general would have punchy low end power, but would lack the speed another 33t may have. This just goes to show how fine you can tune your motor! Now, that may have went over your head. I know alot of the members on this site are younger (believe it or not, I'm only 15), so I know this may be confusing. If your interested in the performance that a finely tuned motor can create, but are not capable of building one on your own, give me a shoutout, and I'd be glad to help you along with it, or build you one myself! So any Comments? Questions? PLEASE FEEL FREE TO MENTION YOUR TECHNIQUES!!! -------------------------------------- Brush and Commutator Tuning These two components are what makes a brushe motor a brushed motor. Needless to say, they play a huge roll in the performance of your motor. Lets start with the Brushes. When the brushes are in contact with the commutator, they are only touching two plates on the comm. This allows current to travel in a circuit. The Negative brush recieves current from the ESC. When it places it onto the commutator and wears, it is actually lubing the comm. Believe it or not, the brushes sediments are assisting in dry lubricating the commutator. Thats why it isn't necessary to glob on your comm drops. The brushes are helping do the work. When the brushes are properly broken in and all of the brush face is being pressed onto the commutator, performance is greatest. However, you can adjust your brushes even further. On the M1 Motor Case, there are brush springs. Different brush springs will affect the wear of the brushes differently. The soft springs, since the tension of the brush on the comm is lowered, friction is reduced. However, the brushes "glaze" the commutator when they wear. "Glazing" eats away at the brushes, and gunks up your commutator. Super-Hard brush springs do almost the opposite. The increase conductivity, but also increase friction, wearing your brushes and commutator just as fast. Medium springs offer a balance between the two, and the regular Hard springs are another option. There aren't to many options as far as upgrading the commutator besides making it bigger. FAT comms are the premier upgrade when it comes to the comm. It increases the tolerance to high current, increases conductivity, and lasts longer than a standard commutator. One thing that larger scale motorists will do is true/lathe their commutators. At this scale, its almost better to buy a new one, but if you have an armature laying around that has a tired, dirty comm, grab some 2500-3000 grit sandpaper and polish it up. It is similar in effect to truing, but you can't sand it perfectly true like a lathe is capable of. When maintaining your commutator, don't worry to much about it, but if there is gunk build up, or scratches, then its best to polish it and remove these minor imperfections because it will lower friction and increase conductivity. Questions? Comments? PLEASE FEEL FREE TO MENTION YOUR TECHNIQUES!!! --------------------------------------- Quick-Azz Trucks? How many X-trucks do you see rolling around with sub-30t motors? Not to many right? Why is that? Because trucks are built to tackle tougher terain. Low wind count motors just don't offer the torque that trucks need. That is why there are very few people running HOT motors. I would like to change that. Now, before you say "But I want to go fast and crawl over stuff!" Think twice. Crawling is very tough on a motor. It requires alot of torque, and to crawl stuff and go fast is NOT an option. The product I'm about to unveil to you is not made for crawling or scaling large obstacles. It is purpose built for going fast on terrain similar to what you'd see at a 1:10 scale Truggy A-Main. This is a Team Redmade Exclusive Product! I'm proud to say that it has not been released by any micro RC company or even really thought of at this scale. I know, it sounds like I'm making a huge deal out of it, but it is a huge deal for me, lol. I'm very proud of my ingenuity (well, its nothing new to RC motors) and have designed a line of motors around it. Introducing the Team Redmade 2x Armature series! These armatures feature a FAT copper commutator, and something extra special. A double wind. Instead of using a single stand of wire to wind the pole, two wires of the same thickness are used. It is offered in 6 different wind counts. 17x2, 18x2, 19x2, 20x2, 21x2, and 22x2. Here's how it works. The total wind count in an 18x2 armature would be 36t. However, since its a double, the motor is recognized as 18t. It'll spin with the low end torque of a 36t motor, but with the scream of an 18t! Here's something extremely similar-a Team Checkpoint 14t double: Problem is, these arematures are difficult to make. I spent around two hours just winding a 17x2 pattern. Plus, there are some minor technicalities to work out, and I'd like some feedback from you guys on this one. Since double is wound into a pattern (first 17 make base, next 17 make top of pyrimid) so basically its using two different lengths of wire. The first set is wide, and short, and the next is tall and long. This may create some problems as far as a balance in powerband goes, but I feel that since these are designed for offroad, the minor imbalance woudn't be to noticeable. Opinions? I talked to Flashsp-2 and he told me that the different lengths create a middle ground between the stack patterns, and I have a feeling he's right (its Flash for god-sakes, lol) But other than that, pretty sweet eh? Its about time that we start seeing some heavily modded off-road dirt junkies with bad-azz high amp Motors! Please feel free to comment or ask questions! ------------------------------------------- Just Say It! Now its your turn. I've shown you what I know, and probably bored most of you to death. Its time for some of you guys to step up and let me know what you know. If you have a tip or a technique that you use just post it. Seriously anything. Like do you prefer Drilling or Epoxy balancing, do you prefer Hemi-Winding, or Straight Winding? Just talk about it, and discuss it here! Please! I'm begging you! Just SAY IT! I learned everything I know by doing. I've been through over 30 stock xmod armatures in my time as a modder, and I'm still burning through them testing out new designs, concepts and idears. Basically saying, if you feel that you wanna try something and your worried about failure, don't be worried. I'm used to failure. But don't think of it like that! You just found out a way that it doesn't work! Once you get good, you can start experimenting with other things, and soon you'll be at a level that your comfortable saying that your a motor guru! I hope that this thread grows, and you guys learn a little something here and there. Like I said so many times before, please comment or ask questions. It'll greatly benefit the modding community! Additional Resources: http://xmodsource.com/forum/showthread.php?t=12999 < How to Pattern Wind http://xmodsource.com/forum/showthread.php?t=12362< Motor "Bible" http://xmodsource.com/forum/showthread.php?t=13116 < Team Redmade Motors http://www.bigjimracing.com/tuningtips.php < Some Very Good Motor Info (although for larger scale motors) Later, RedSXmodder Last edited by RedSXmodder; 12-28-2008 at 05:15 PM.. |

|

#3

|

||||

|

||||

|

Very Nice write up red.

I just wish they would start making some of those special armatures again. there are hardly any left. I have 2 left un wound. Take Time when winding. I am not an advanced winder but i can at least see a performance gain in my motors over the s2 and s1 motors. Spider v4s and the bug or stacked nellies are a great upgrade for motor winders, puts their abilities to the test. Congrats on the truck armature man. More to come.

__________________

Track car v2.0 fieldfairy2's mini late model Operation black widow H-Crawler

|

|

#4

|

|||

|

|||

|

Great write up, it leaves me with my little winding experience nothing to add...LOL

In your first picture what is that armature way to the left for? Whats the balance on it? Also i dont quite understand the turn placement part. If you place the turns farther to the outside of the poles isn't that all around better? EDIT: Wait nevermind i dont know what i was thinking. rotational mass. Farther outside = more torque. Farther inside = Higher RPMS... |

|

#5

|

||||

|

||||

|

nice.

but i'm one of those rare few who use almost exclusively sub 30t motors in my car and truck. (27t Xtruck) but this info is really good i was just thinking of doing double wound armatures... i hear they are smoother. i just can't find a good source of motor wire all i can do is get RS magnet wire. WOAH you're 15? so am i! anyways, how is it possible for you to fit so many winds on the bottom layer? i can only get 8-9 winds before i run out of space on the rotor.

__________________

|

|

#8

|

||||

|

||||

|

Quote:

http://www.auldey.com/aulde/product/...ntCategoryID=2 Have you checked out my Pattern Winding tut? It may help you with your winding. Just remember, practice, practice practice! Quote:

Thanks for the comment! Quote:

I'm pretty much exclusively using RS wire ATM. It works great, is cheap, and looks good! However, I wish that they would make 28awg wire though. 26 works good, but its a smidge to big. I know that the Auldey page I posted previously has a bunch of silver coated wires that would be great! Your 15 too? Oh the irony...lol. When I wind, I wind on arms that have the resin shield instead of the white plastic ones. If they don't have the resin shield, I put a clear laquer over the tops of the poles to prevent shorting. Without these shields, you should be able to squeeze 10 and if your lucky 11 on the bottom row. Thanks for the comment! I would like to, but they is expenzive!!! Thanks for the comment, tho... Quote:

Later, RedSXmodder |

|

#9

|

||||

|

||||

|

You're still around?

Well, I guess you need the advertising to fund your film habits. ;p You want to wind me up a X-2 LightSpeed or Cheatah (Donzii will know about it) type motor?

__________________

After a thousand years of oppression,

Let the berserks rise again, Let the world hear these words once more: "Save us, oh lord, from the wrath of the Norsemen" |

|

#10

|

||||

|

||||

|

i just totally enjoy winding motors. i think that the last single strand on top is a bit hard to get to stay there. i use elmers glue to hold it on.

and anyways, i tried to use elmers glue instead of lacuer, and idk if it works yet. i'll have to see when i get home from school.

__________________

|

|

#13

|

||||

|

||||

|

Quote:

Quote:

Later, RedSXmodder |

|

#15

|

||||

|

||||

Discuss! One thing I'd like to point out in these armatures is that there is a ton of potential as far as tuning goes. I'm 100% positive that this armature (or any carefully made double for that matter) will be an excellent addition to any x-truckers arsenal, and may even spark interest in Rally cars, or to get even farther out there, some dirt oval action. Wouldn't that be kick ***? However, one thing that would be very worthwhile looking into is a double, on a Spiral armature! I mean, seriously, here's what I was thinking: M1 Motor Case (Hard brush springs, because it has enough torque, and doesn't need anymore RPM) Spiral Armature with a 21x2 pattern (Torque out the wahzoo, plus RPM to spare) FAT copper comm (will last alot longer than wimpy standard comms, and handle the voltage better too) Neodiymium Motor Magnets (These monsters will give the motor a majority of its torque) Properly break the motor in, drill the armature, lube it up, give it some comm drops, and feed it 7.4v, and this thing will tear up the dirt! Like I said, there is alot of potential to be had, however, the fan base won't be as large as car motors. Later, RedSXmodder |

|

#16

|

||||

|

||||

|

That new arm is deadly. Those pictures are fantastic, I might shoot some of my products towards donzii

__________________

Feel free to ask me anything Xmods related. Chances are I know the answer, or can tell you someone that does. Mercedes Track Car v2 (50% finished) : http://www.xmodsource.com/forum/showthread.php?t=18360 Comeback Supra Project (trust me tune in): http://www.xmodsource.com/forum/showthread.php?t=20546 |

|

#18

|

||||

|

||||

|

How does dual pyramid work? I wanna start winding

I've tried, I'm not good. I've tried, I'm not good.

__________________

Feel free to ask me anything Xmods related. Chances are I know the answer, or can tell you someone that does. Mercedes Track Car v2 (50% finished) : http://www.xmodsource.com/forum/showthread.php?t=18360 Comeback Supra Project (trust me tune in): http://www.xmodsource.com/forum/showthread.php?t=20546 |

|

#19

|

||||

|

||||

|

I've found it tougher to wind the double in a hemi-wind pattern. Its hard enough like this. Maybe I'll get around to trying hemi style. Deffinately would make things seem smoother...

Dual pyrimid probably won't happen, or at least won't be tested unless I get some more time on my hands, lol. I've been swamped recently. Later, RedSXmodder |

|

#20

|

||||

|

||||

|

this is kinda OT but if i take the motor out of a stage 3 gen 1 can and put it in a evo can will it still make me car faster or is the speed all in da gearing?

__________________

|

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

|

|